Maintenance Tips for Drone Motor

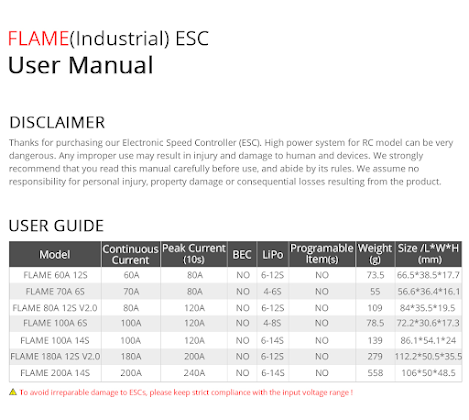

Welcome to our comprehensive guide on maintaining drone motors for optimal performance and longevity. Drones have become an indispensable tool in various industries, from photography and videography to agriculture and surveillance. Like any other mechanical device, drone motors require regular maintenance to ensure they operate efficiently and reliably. In this article, we will delve into maintenance tips specifically tailored to drone motors, helping you extend their lifespan and maximize their performance. Before diving into maintenance tips, it's essential to understand the basics of drone motors. Most drones utilize brushless DC motors due to their efficiency, reliability, and longevity. These motors consist of several key components, including stator coils, rotor magnets, bearings, and electronic speed controllers (ESCs). Understanding how these components work together is crucial for effective maintenance. Pre-flight Inspection The first step in maintaining your drone